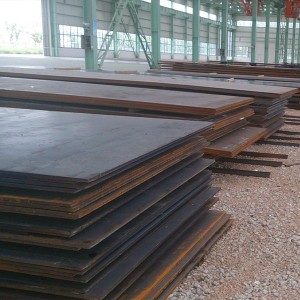

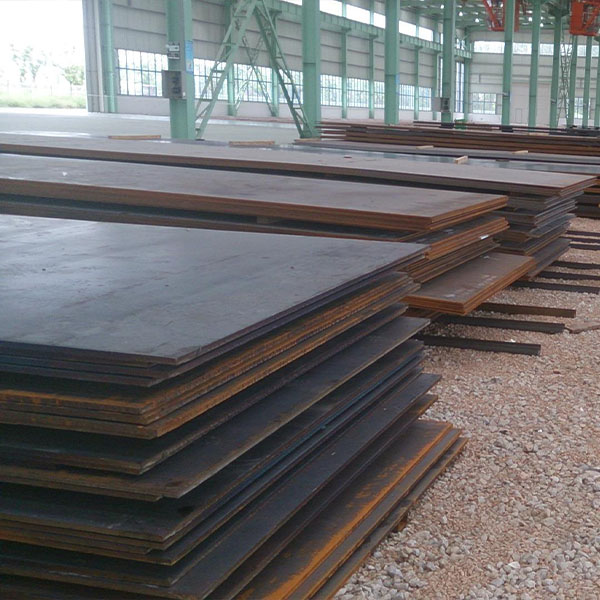

Carbon Karfe Boiler Plate

farantin karfe (s) don gadoji

Dutsen gada wani farantin karfe ne mai kauri wanda aka sadaukar don kera sassan tsarin gada. An yi shi da ƙarfe na carbon da ƙananan ƙarfe don gina gada tare da matakan ƙarfe na musamman. Ƙarshen lambar ƙarfe ana yiwa alama da kalmar q (gada).Carbon karfe don gina gada ya haɗa da A3q don tsarin gada da 16q don tsarin walda; low-alloy karfe ga gada Tsarin hada 12Mnq, 12MnVq, 15MnVNq, 16Mnq, da dai sauransu A kauri daga cikin gada karfe farantin ne 4.5-50 mm.

Yankunan aikace-aikace:

Gadajen titi da gadoji na dogo da ake amfani da su wajen kera riveted da welded welded, ciki har da gadoji na tsallaka teku, da dai sauransu.

| Farantin karfe don gada | Daraja | Matsayin gudanarwa | Magana |

| 16q, 16Mnq, 16MnCuq15MnVq, 15MnVNq14MnNbp, Q345q, Q420qA709M (Gr36, 50, 50W, 70W) | YB168kumaYB(T) 10GB/T714ASTM | 1. Za a iya samar da Z15-Z35 daban-daban maki na anti-lamellar tearing (kauri shugabanci yi) karfe faranti. 2. Ƙididdigar samarwa: kauri 8mm-400mm, nisa 1500mm-3900mm, tsawon 3000mm-18000mm. Bangarorin biyu sun amince da samar da farantin karfe mafi girma. 3. Bisa ga aiki da bukatun mai amfani, matsayi na bayarwa na farantin karfe na iya zama mai zafi mai zafi, sarrafawa mai sarrafawa, daidaitawa, da kuma cirewa. |

Laser tela-welded mara kyau da ci gaba mai canzawa fasahar hukumar giciye

1. Tailor Welded Blanks (Tailor Welded Blanks, TWB) yana amfani da Laser a matsayin tushen zafi na walda don haɗawa da walda abubuwa da yawa daban-daban, nau'i daban-daban, da nau'i daban-daban na karfe, bakin karfe, aluminum gami, da dai sauransu a cikin babban farantin.

2. Yin amfani da fasahar walƙiya da aka keɓance Laser, yana yiwuwa a haƙiƙa haɗa kayan nau'ikan nau'ikan kauri daban-daban da matakan ƙarfi bisa ga yanayin damuwa na sassan tsarin, haɓaka ƙaƙƙarfan tsarin yayin rage nauyin sassa, da haɓaka ƙimar amfani. na kayan da rage yawan sassa. Adadin sassa a cikin sauƙaƙe tsari. Fasahar walda da aka kera ta Laser ta zama babbar hanyar fasaha ta mota mara nauyi, kuma an yi amfani da ita ga samfuran masana'anta da yawa. An fi amfani dashi a gaba da baya kofa na ciki, gaba da baya na tsayin tsayi, bangarorin gefe, ginshiƙan bene, ginshiƙan A, B, da C a cikin ƙofar, murfin dabaran da bangarorin ciki, da sauransu.

3. Tailor Rolling Blanks (TRB), wanda kuma ake kira bambancin kauri, yana nufin canji na ainihin lokacin girman gibin nadi ta hanyar kwamfuta yayin aikin narkar da farantin karfe, ta yadda farantin da aka yi birgima yana da riga-kafi. shugabanci tare da mirgina shugabanci. Siffar juzu'i mai canzawa ta al'ada.

4. Ci gaba da m giciye-section panel fasahar da aka yadu amfani a yi na jiki tsarin sassa, kamar engine cover, B-ginshiƙi, jiki chassis, motor spacer jagora, tsakiyar shafi ciki panel, laka da kuma hadarin akwatin, da dai sauransu. kuma an yi nasarar amfani da Audi, BMW, Volkswagen, GM da sauran samfuran.

5. Laser wanda aka keɓance waldi da ci gaba da fasahar keɓaɓɓiyar fasaha na canza kauri na kayan hatimi ta hanyar fasaha daban-daban, kuma ana amfani da su don magance matsalar buƙatun ƙarfin ɗaukar nauyi daban-daban don sassa daban-daban na sassan auto ƙarƙashin kaya. Idan aka kwatanta da biyun, fa'idar tela da aka yi da fasahar walda ta Laser ta ta'allaka ne a cikin sassaucin ra'ayi, wanda zai iya gane splicing na kowane matsayi da splicing na daban-daban kayan. A amfani da ci gaba m giciye-sashe fasaha ne cewa babu waldi kabu, da taurin canji tare da tsawon shugabanci ne in mun gwada m, yana da mafi kyau formability, da kuma surface quality ne mai kyau, da samar da inganci ne high, da kuma kudin ne. ƙananan. Kayayyaki, kayan aikin likita, harsashi babur; mota, rufin ciki na bas, dashboard; wurin zama goyon baya, kofa panel, taga frame, da dai sauransu.