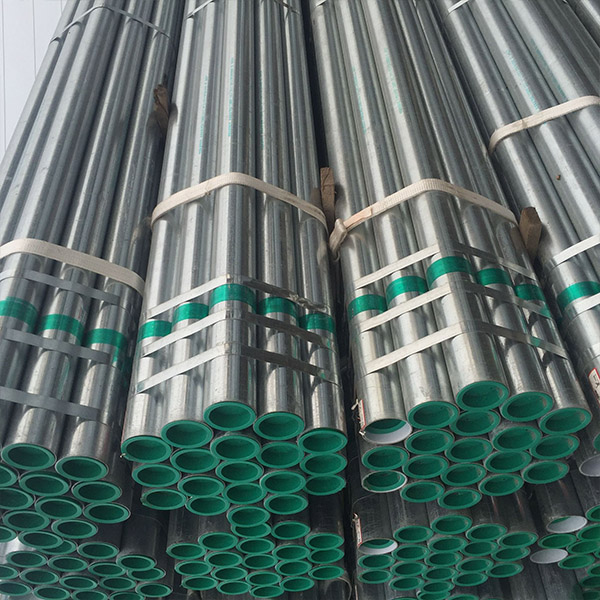

Cold Galvanized Karfe bututu, Hot-Tsama Galvanized Karfe bututu

1. Pre-galvanized: Pre-galvanized karfe bututu ne kai tsaye sarrafa daga zafi-tsoma galvanized karfe tsiri.

Galvanized Layer: 40-60g / sm, idan ana buƙatar ƙarin galvanized Layer, ana iya sarrafa shi bisa ga tsari. (Kauri shine 0.7mm-4.5mm)

2. Hot-tsoma galvanized: Hot-tsoma galvanized bututu yana da kauri tutiya shafi fiye pre-galvanized bututu. Baƙar fata bututun karfe za a nutsar da shi a cikin wankan zinc don yin galvanizing. Tutiya shafi na iya zama: 200-500g/sm

Tsarin tafiyar shine:baƙar fata-alkaline wankin-ruwa-wanke-ruwan kurkura-jika taimako-bushe-zafi tsoma galvanizing-na waje hura-na ciki hurawa-iska sanyaya-ruwa sanyaya -Passivation-ruwa kurkura-duba-auna-ajiya.

1. Brand da sinadaran abun da ke ciki

Matsayi da sinadarai na ƙarfe don bututun ƙarfe na galvanized ya kamata su bi ka'ida da sinadarai na ƙarfe don bututun baki kamar yadda aka ƙayyade a GB/T3091.

2. Hanyar sarrafawa

Hanyar masana'anta na bututun baƙar fata (welding na makera ko waldi na lantarki) an zaɓi mai ƙira. Ana amfani da galvanizing mai zafi don yin galvanizing.

3. Zare da bututu haɗin gwiwa

(A) Domin galvanized karfe bututu da aka kawo tare da zaren, zaren ya kamata a yi machined bayan galvanizing. Zaren ya kamata ya bi ka'idodin YB 822.

(B) Ya kamata haɗin haɗin bututun ƙarfe ya dace da YB 238; Malleable simintin gyare-gyaren bututun ƙarfe yakamata ya dace da YB 230.

4. Mechanical Properties The inji Properties na karfe bututu kafin galvanizing kamata hadu da bukatun na GB 3091.

5. Ya kamata a gwada daidaitattun nau'i na galvanized Layer Galvanized karfe bututu ya kamata a gwada don daidaitaccen ma'auni na galvanized Layer. Samfurin bututun ƙarfe ba zai zama ja (launi mai launin jan karfe) ba bayan an nutsar da shi cikin maganin sulfate na jan karfe na sau 5 a jere.

6. Gwajin lanƙwasa sanyi Bututun ƙarfe na galvanized tare da diamita mara kyau wanda bai wuce 50mm ba yakamata a yi gwajin lanƙwasa sanyi. Kwanin lankwasawa shine 90°, kuma radius na lanƙwasawa shine sau 8 na diamita na waje. Babu filler a lokacin gwajin, kuma weld na samfurin ya kamata a sanya a waje ko na sama part na lankwasawa shugabanci. Bayan gwajin, kada a sami fasa da kwasfa na Layer na zinc akan samfurin.

7. Gwajin gwajin ruwa Ya kamata a yi gwajin gwajin ruwa a cikin clarinet. Hakanan ana iya amfani da gano aibi na Eddy a maimakon gwajin matsa lamba na ruwa. Matsakaicin gwajin gwaji ko girman samfurin kwatancen don gwajin eddy na yanzu zai cika buƙatun GB 3092. Kayan aikin injiniya na ƙarfe shine mahimmin mahimmanci don tabbatar da aikin ƙarshe na amfani (kayan aikin injiniya) na ƙarfe.

Shandong Jinbaicheng Metal Material Co., Ltd. is located in Shandong, mafi girma a duniya welded samar da bututu tushe. Bayan shekaru na aiki tuƙuru, an kafa tsarin bunƙasa zuba jari iri-iri. Dangane da buƙatun sabbin masana'antu, muna ba da cikakkiyar wasa ga fa'idodinmu don cimma ma'auni, tsari, da inganci. Cikakken haɓaka fa'idodi.

Mun kware a sayar da galvanized karfe bututu, zafi-birgima karfe bututu, sumul bututu,. Bayan shekaru da yawa na ci gaba, mun kafa dogon lokaci

Haɗin kai tare da abokan ciniki daga ƙasashe sama da 70 a duniya, gami da Kanada, Australia, Singapore, Thailand, Koriya ta Kudu, Vietnam, Mexico, Chile, Peru, da New Zealand. Abubuwan da ake fitarwa a shekara shine ton 700,000.

Hanyar haɗin bututun ƙarfe na galvanized: threaded, welded.

Mirgine haɗin tsagi

(1) Fatsawar nadi tsagi walda

1. Sauƙaƙe haƙarƙarin walda na bangon ciki na ɓangaren matsa lamba na bututun ƙarfe don rage juriya na mirgine tsagi.

2, Daidaita axis na karfe bututu da mirgina grooving kayan aiki, da kuma bukatar karfe bututu da mirgina grooving kayan aiki zama matakin.

3. Daidaita tsagi mai saurin matsawa, kuma lokacin yin tsagi ba zai iya wuce ƙa'idar ba, yi amfani da karfi a ko'ina kuma a hankali.

(2) Roll tsagi karfe bututu karaya

1. Sauƙaƙe haƙarƙarin walda na bangon ciki na ɓangaren matsa lamba na bakin bututu don rage juriya na birgima.

2, Daidaita axis na karfe bututu da mirgina tsagi kayan aiki, bukatar karfe bututu da mirgina grooving kayan aiki ya zama matakin.

3. Daidaita saurin latsawa, saurin matsawa ba zai iya wuce ƙa'idar ba, yi amfani da karfi a ko'ina kuma a hankali.

4. Bincika nisa da samfurin abin nadi na goyan baya da matsi na nadi na nadi na mirgina kayan aiki, da kuma duba ko akwai rashin daidaituwa a cikin girman rollers biyu, wanda zai iya haifar da kama.

5. Yi amfani da caliper na vernier don bincika ko an ƙayyade tsagi na bututun ƙarfe.

(3) Tsagi da aka kafa ta na'ura mai juyi ya kamata ya dace da waɗannan buƙatun

1, Ƙarshen ƙarshen bututu zuwa sashin tsagi ya kamata ya zama santsi kuma ba tare da rashin daidaituwa da alamun mirgine ba.

2, Tsakiyar tsagi ya kamata ya zama mai hankali tare da bangon bututu, nisa da zurfin tsagi ya kamata ya dace da buƙatun, kuma duba ko nau'in nau'in nau'in nau'in nau'i daidai ne.

3. A shafa mai a zoben rufe roba sannan a duba ko zoben da ke rufe roba ya lalace. Dole ne man shafawa ya zama mai mai.

Haɗin walda

1. Bakin bututun bututun ƙarfe ba ya cikin layi madaidaiciya kuma ana samun matsala tare da bakin bututun ƙarfe bayan butt. Ana ba da shawarar yanke kan bututu na ɗan gajeren lokaci kafin aiki.

2, Bayan da galvanized karfe bututu nozzles an haɗa, biyu nozzles ba tam alaka, haifar da m kauri na welded hadin gwiwa; kuma bututun yana da elliptical saboda nasa dalilai ko na sufuri. Ana ba da shawarar yanke kan bututu na ɗan gajeren lokaci. A sake aiwatarwa.

3. Bayan nozzles na galvanized karfe bututu an butted, blisters bayyana a nozzles:

4. Saboda dalilai na fasaha a lokacin walda.

5. Akwai nodules na zinc a cikin bututun ƙarfe, wanda zai iya haifar da matsalolin walda da blisters. Idan nodules na zinc sun yi girma da yawa kuma bututu masu yawa, ya kamata a cire nodules na zinc mai sauƙi.

Haɗin waya

1, Zare Zare: Ba za a iya tuntuɓar bututun bututu da zaren zaren gaba ɗaya ba, sassautawa, yanke ɓangaren zaren bazuwar, sannan a sake shigar da zaren.

2. Zaren bututun ƙarfe da zaren hoop ɗin bututu ba su dace ba kuma ba za a iya haɗa su ba. Dole ne a maye gurbin bututun bututu ko kuma a gyara kayan aikin kuma a sake zare su.

3. Bacewar bugu bayan an zare bututun ƙarfe: Auna ko kaurin bangon bututun ƙarfe zai iya biyan daidaitattun buƙatun kauri na bututun da aka zare.

| Nau'in | En10210 galvanized karfe bututu |

| Daraja | S235jrh(1.0039) 5.9 (1.0512), 7 (9), 7 (9), 5.9 (1.0512), s27 (1.0512), s27 (1.0149), s275j2h (1.0138), s355j0h (1.0547) s420nh (1.8750) s460nh (1.8953) s355j2h (1.0552) (1.0493), s275nlh (1.0497), s355nh (1.0539), s355nlh (1.0549), s420nh (1.8750), s420nlh (1.8750), s420nlh (1.3h.8) s460nlh (1.8956) , s275mh (1.8453) (m843) s275ml (s355mlh (1.8846) s420mh (1.8847) s420mlh (1.8848) s460mh |

| Kauri | 3mm - 30mm |

| Takaddun shaida | Ul api |

| Sabis ɗin sarrafawa | Lankwasawa, walda, kwancewa, naushi, yanke |

| Sunan samfur | Bututun ƙarfe mara nauyi |

| Siffar | Dandalin zagaye. Rectangle |

| Tsawon | 3-12m |

| Moq | 1 ton |

| Fasaha | Zafafan mirgina sanyi |