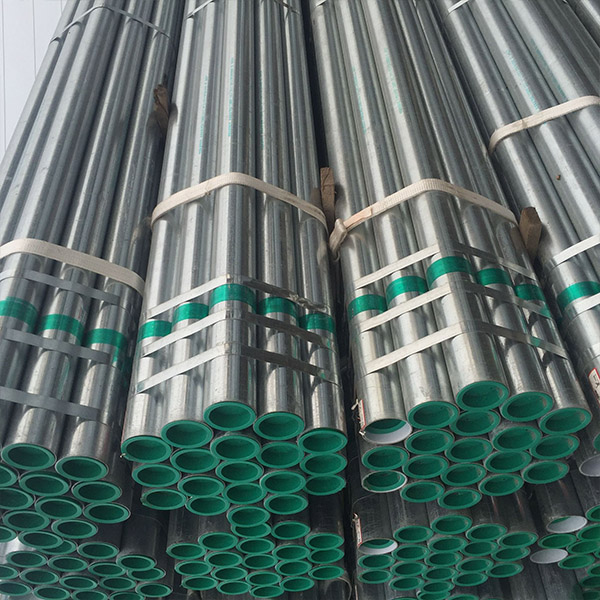

Galvanized bututu

Tsarin tafiyar shine:baƙar fata-alkaline wankin-ruwa-wanke-ruwan kurkura-jika taimako-bushe-zafi tsoma galvanizing-na waje hura-na ciki hurawa-iska sanyaya-ruwa sanyaya -Passivation-ruwa kurkura-duba-auna-ajiya.

1, Brand da sinadaran abun da ke ciki

Matsayi da sinadarai na ƙarfe don bututun ƙarfe na galvanized ya kamata su bi ka'ida da sinadarai na ƙarfe don bututun baki kamar yadda aka ƙayyade a GB/T3091.

2, Hanyar masana'antu

Hanyar masana'anta na bututun baƙar fata (welding na makera ko waldi na lantarki) an zaɓi mai ƙira. Ana amfani da galvanizing mai zafi don yin galvanizing.

3. Thread da bututu haɗin gwiwa

(a) Don bututun ƙarfe na galvanized da aka kawo da zaren, zaren ya kamata a yi injin bayan yin galvanizing. Zaren ya kamata ya bi ka'idodin YB 822.

(b) Gilashin bututun ƙarfe ya kamata ya dace da YB 238; Malleable simintin gyare-gyaren bututun ƙarfe yakamata ya dace da YB 230.

4. Mechanical Properties The inji Properties na karfe bututu kafin galvanizing kamata hadu da bukatun na GB 3091.

5. Dole ne a gwada daidaituwa na galvanized Layer Galvanized karfe bututu ya kamata a gwada don daidaitaccen ma'auni na galvanized Layer. Samfurin bututun ƙarfe ba zai zama ja (mai-plated tagulla) ba bayan an nutsar da shi cikin maganin sulfate na jan karfe na sau 5 a jere.

6, Cold lankwasa gwajin galvanized karfe bututu tare da maras muhimmanci diamita na ba fiye da 50mm ya kamata sanyi lankwasawa gwajin. Kwanin lankwasawa shine 90°, kuma radius na lanƙwasawa shine sau 8 na diamita na waje. Babu filler a lokacin gwajin, kuma weld na samfurin ya kamata a sanya a waje ko na sama part na lankwasawa shugabanci. Bayan gwajin, kada a sami fasa da kwasfa na Layer na zinc akan samfurin.

7, Gwajin gwajin ruwa Ya kamata a yi gwajin gwajin ruwa a cikin clarinet, kuma ana iya amfani da gwajin eddy a maimakon gwajin gwajin ruwa. Matsakaicin gwajin gwaji ko girman samfurin kwatancen don gwajin eddy na yanzu zai dace da bukatun GB 3092. Kayan aikin injiniya na ƙarfe sune mahimman alamomi don tabbatar da aikin amfani na ƙarshe (kayan aikin injiniya) na ƙarfe.

Ƙarfin ƙarfi (σb):Matsakaicin ƙarfin (Fb) wanda samfurin ya ɗauka lokacin da ya karye yayin aikin shimfidawa, rarraba ta hanyar damuwa (σ) da aka samu ta hanyar rarraba asalin yanki na yanki (So) na samfurin, ana kiransa ƙarfin ƙarfin juriya (σb) , Naúrar ita ce N/mm2 (MPa). Yana wakiltar iyakar ƙarfin kayan ƙarfe don tsayayya da lalacewa a ƙarƙashin ƙarfi. A cikin dabara: Fb-mafi girman ƙarfin da samfurin ke ɗauka lokacin da ya karye, N (Newton); Don haka-ainihin yanki na giciye na samfurin, mm2.

Matsayin Haɓakawa (σs):Don kayan ƙarfe tare da abin da ya faru na yawan amfanin ƙasa, damuwa wanda samfurin zai iya ci gaba da tsawo ba tare da ƙara ƙarfin ba a lokacin tsarin shimfidawa ana kiransa alamar amfanin gona. Idan ƙarfin ya ragu, ya kamata a bambanta maki na sama da na ƙasa. Nau'in ma'aunin yawan amfanin ƙasa shine N/mm2 (MPa). Matsayin Haɓaka Ƙarfafa (σsu): Matsakaicin damuwa kafin samfurin ya haifar da raguwar ƙarfi a karon farko; Ƙarƙashin Ƙarfafa Haɓaka (σsl): Matsakaicin danniya a matakin yawan amfanin ƙasa lokacin da ba a la'akari da tasirin wucin gadi na farko ba. Inda: Fs - ƙarfin amfanin ƙasa (m) yayin aiwatar da juzu'i na samfurin, N (Newton) Don haka - asalin yanki na giciye na samfurin, mm2.

③ Tsawaitawa bayan karya:(σ) A cikin gwajin gwaji, yawan adadin tsawon tsawon ma'auni ya karu bayan an karya samfurin zuwa tsawon ma'auni na asali ana kiransa elongation. An bayyana ta σ, rukunin shine%. A cikin dabara: L1-tsawon ma'auni na samfurin bayan karya, a cikin mm; L0-tsawon ma'aunin asali na samfurin, a mm.

④ Rage yanki:(ψ) A cikin gwajin gwagwarmaya, adadin matsakaicin matsakaicin raguwa na yanki na yanki a raguwar diamita na samfurin bayan an karya samfurin zuwa asalin yanki na asali ana kiransa raguwar yanki. An bayyana a cikin ψ, naúrar ita ce%. A cikin dabara: S0-ainihin yankin giciye na samfurin, mm2; S1-mafi ƙarancin yanki na giciye a raguwar diamita na samfurin bayan ya karye, mm2.

⑤ Ma'anar Hardness:Ƙarfin kayan ƙarfe don tsayayya da shigar da abubuwa masu wuya a saman ana kiransa hardness. Dangane da hanyoyin gwaji daban-daban da iyakokin aikace-aikacen, za a iya raba taurin zuwa taurin Brinell, taurin Rockwell, taurin Vickers, taurin bakin teku, taurin micro da taurin zafin jiki. Akwai bututu guda uku da aka fi amfani da su: Brinell, Rockwell, da taurin Vickers.

Brinell hardness (HB):Yi amfani da ƙwallon ƙarfe ko simintin carbide ball tare da takamaiman diamita don danna shi cikin saman samfurin tare da ƙayyadadden ƙarfin gwaji (F), cire ƙarfin gwajin bayan ƙayyadadden lokacin riƙewa, kuma auna diamita na shigarwa a saman saman. misali (L). Ƙimar taurin Brinell ita ce ƙimar da aka samu ta hanyar rarraba ƙarfin gwajin ta wurin sararin samaniya na indentation. An bayyana shi a cikin HBS (ball karfe), naúrar ita ce N/mm2 (MPa).