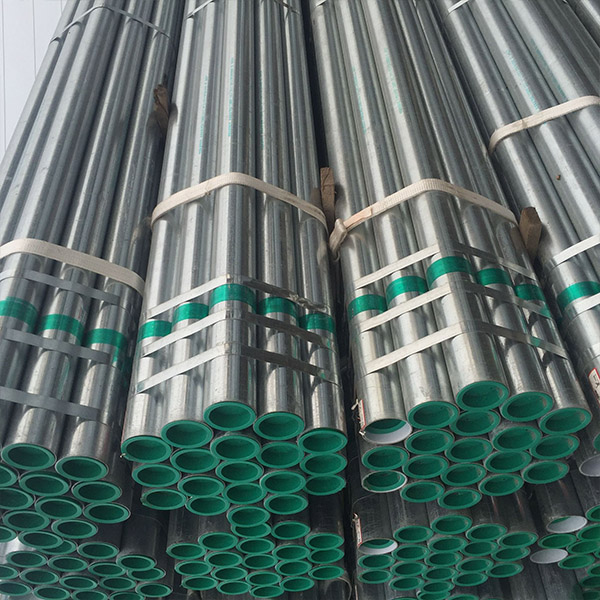

Hot tsoma Galvanized Karfe

Kaurin bango mara iyaka (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Ƙididdigar ƙididdiga (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Lura: Kayan aikin injiniya na karfe shine mahimman bayanai don tabbatar da aikin amfani na ƙarshe (kayan aikin injiniya) na karfe, kuma ya dogara da sinadarai na karfe da tsarin kula da zafi. A cikin ma'auni na bututun ƙarfe, bisa ga buƙatun aikace-aikacen daban-daban, kaddarorin ƙwanƙwasa (ƙarfin ƙarfi, ƙarfin yawan amfanin ƙasa ko ma'aunin yawan amfanin ƙasa, elongation),An ƙayyadaddun fihirisar taurin ƙarfi da taurin kai, da maɗaukaki da ƙananan kaddarorin zafin jiki waɗanda masu amfani ke buƙata.

Makin ƙarfe: Q215A; Q215B; Q235A; Q235B.

Ƙimar gwaji / Mpa: D10.2-168.3mm shine 3Mpa; D177.8-323.9mm shine 5Mpa

Ma'auni na ƙasa da ma'aunin girman girman bututun galvanized

GB/T3091-2015 Welded karfe bututu don low matsa lamba ruwa sufuri

GB/T13793-2016 Dogon lantarki welded karfe bututu

GB/T21835-2008 welded karfe bututu size da naúrar tsawon nauyi

Tsarin tafiyar shine:baƙar fata-alkaline wankin-ruwa-wanke-ruwan kurkura-jika taimako-bushe-zafi tsoma galvanizing-na waje hura-na ciki hurawa-iska sanyaya-ruwa sanyaya -Passivation-ruwa kurkura-duba-auna-ajiya.

Bututun da aka saba cewa, bututun galvanized ana amfani da iskar gas, da kuma irin bututun ƙarfe da ake amfani da su don dumama bututun da ake amfani da su. Ana amfani da bututun galvanized azaman bututun ruwa. Bayan an yi amfani da shekaru da yawa, ana haifar da tsatsa da datti mai yawa a cikin bututu, kuma ruwan rawaya da ke fitowa ba wai kawai ya gurɓata kayan aikin tsafta ba , Kuma an haɗe shi da ƙwayoyin cuta waɗanda ke haifuwa a bangon ciki marar daidaituwa, kuma lalata yana haifar da lalata. yawan karafa masu nauyi a cikin ruwa, wanda ke yin illa ga lafiyar jikin dan Adam matuka.

Hanyar haɗin bututun ƙarfe na galvanized: threaded, welded.

Mirgine haɗin tsagi

(1) Fatsawar nadi tsagi walda

1. Sauƙaƙe haƙarƙarin walda na bangon ciki na ɓangaren matsa lamba na bututun ƙarfe don rage juriya na mirgine tsagi.

2, Daidaita axis na karfe bututu da mirgina grooving kayan aiki, da kuma bukatar karfe bututu da mirgina grooving kayan aiki zama matakin.

3. Daidaita tsagi mai saurin matsawa, kuma lokacin yin tsagi ba zai iya wuce ƙa'idar ba, yi amfani da karfi a ko'ina kuma a hankali.

(2) Roll tsagi karfe bututu karaya

1. Sauƙaƙe haƙarƙarin walda na bangon ciki na ɓangaren matsa lamba na bakin bututu don rage juriya na birgima.

2, Daidaita axis na karfe bututu da mirgina tsagi kayan aiki, bukatar karfe bututu da mirgina grooving kayan aiki ya zama matakin.

3. Daidaita saurin latsawa, saurin matsawa ba zai iya wuce ƙa'idar ba, yi amfani da karfi a ko'ina kuma a hankali.

4. Bincika nisa da samfurin abin nadi na goyan baya da matsi na nadi na nadi na mirgina kayan aiki, da kuma duba ko akwai rashin daidaituwa a cikin girman rollers biyu, wanda zai iya haifar da kama.

5. Yi amfani da caliper na vernier don bincika ko an ƙayyade tsagi na bututun ƙarfe.

(3) Tsagi da aka kafa ta na'ura mai juyi ya kamata ya dace da waɗannan buƙatun

1, Ƙarshen ƙarshen bututu zuwa sashin tsagi ya kamata ya zama santsi kuma ba tare da rashin daidaituwa da alamun mirgine ba.

2, Tsakiyar tsagi ya kamata ya zama mai hankali tare da bangon bututu, nisa da zurfin tsagi ya kamata ya dace da buƙatun, kuma duba ko nau'in nau'in nau'in nau'in nau'i daidai ne.

3. A shafa mai a zoben rufe roba sannan a duba ko zoben da ke rufe roba ya lalace. Dole ne man shafawa ya zama mai mai.

Haɗin walda

1. Bakin bututun bututun ƙarfe ba ya cikin layi madaidaiciya kuma ana samun matsala tare da bakin bututun ƙarfe bayan butt. Ana ba da shawarar yanke kan bututu na ɗan gajeren lokaci kafin aiki.

2, Bayan da galvanized karfe bututu nozzles an haɗa, biyu nozzles ba tam alaka, haifar da m kauri na welded hadin gwiwa; kuma bututun yana da elliptical saboda nasa dalilai ko na sufuri. Ana ba da shawarar yanke kan bututu na ɗan gajeren lokaci. A sake aiwatarwa.

3. Bayan nozzles na galvanized karfe bututu an butted, blisters bayyana a nozzles:

4. Saboda dalilai na fasaha a lokacin walda.

5. Akwai nodules na zinc a cikin bututun ƙarfe, wanda zai iya haifar da matsalolin walda da blisters. Idan nodules na zinc sun yi girma da yawa kuma bututu masu yawa, ya kamata a cire nodules na zinc mai sauƙi.

Haɗin waya

1, Zare Zare: Ba za a iya tuntuɓar bututun bututu da zaren zaren gaba ɗaya ba, sassautawa, yanke ɓangaren zaren bazuwar, sannan a sake shigar da zaren.

2. Zaren bututun ƙarfe da zaren hoop ɗin bututu ba su dace ba kuma ba za a iya haɗa su ba. Dole ne a maye gurbin bututun bututu ko kuma a gyara kayan aikin kuma a sake zare su.

3. Bacewar bugu bayan an zare bututun ƙarfe: Auna ko kaurin bangon bututun ƙarfe zai iya biyan daidaitattun buƙatun kauri na bututun da aka zare.